The process analysis design for the lost foam casting of the three-way pipe are mainly carried out in the shaft sleeve casting factory. Firstly, the quality requirements technical requirements of the parts are analyzed, then the casting process analysis process parameters are analyzed selected in combination with the lost foam casting technology. Based on the prices of various mechanical castings, the purpose is to design excellent lost foam casting of the three-way pipe Manufacturing process, product parts produced.

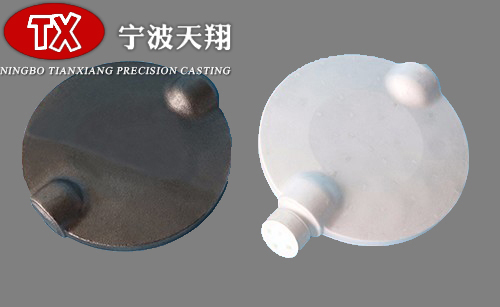

Material of tee pipe parts: gray cast iron (HT200) production requirements: mass production, annual output of 10000t, single part weight: 6.5kg tee pipe is a kind of pipe fitting, which is mainly used to change the direction of fluid. The tee pipe in this design is T-shaped tee pipe with different pipe diameter. The outline dimension of the tee pipe part drawing is 140mm * 85mm * 102.5mm, the main thickness is the wall thickness of the tee pipe of 5mm, which is also a small thickness. The quotation of mechanical casting calculates a series of parameters such as the size shape of the sprue. This part is a small part. Because the wall thickness of the casting is relatively small, it is necessary to ensure the uniformity of the wall thickness of the casting as well as the accuracy of the geometric dimension of the casting, so as to prevent the uneven stress. In addition, it is also necessary to prevent the occurrence of blisters, looseness, shrinkage cavity, carbon defects other defects. Therefore, the tee parts have high quality requirements.

Tee joint is a common part in pipeline installation, which mainly plays the role of diverting expenditure.

According to the different liquid flowing through the tee, its working environment is also different, so the requirements for the tee are different.