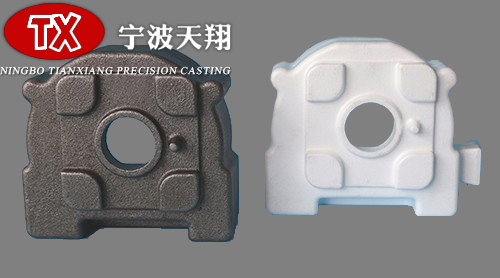

The tee pipe of the mechanical casting supplier is only used for the branch of water flow, there is no special requirement for the wholesale of mechanical casting, but the common point of the mechanical casting manufacturer is that all pipes are subject to radial tension. In order to prevent this factor causing the pipe to expand crack, we should a reasonable pouring temperature during the pouring, so that the castings can be evenly cooled, the residual stress of the castings can be reduced, the casting can be ensured at the same time The wall thickness of the parts is even, extending its service life. In addition, when casting the castings, we must strictly abide by the correct operation of the casting process, strengthen the safety awareness, at the same time, we should consider simplifying the steps to improve the casting value. According to the use requirements conditions of tee pipe, this paper analyzes studies, sums up its own design scheme: as there are no other special quality requirements for castings except for the reduction of defects, while meeting the quality requirements, it is also necessary to meet the requirements of casting process for part structure, review the part structure. The structure of tee pipe parts is simple symmetrical, which conforms to the casting production It is easy to use symmetrical parting foam to ensure the quality of castings improve the production efficiency reduce the cost. After analyzing the structural characteristics technical requirements of tee pipe parts, the following aspects should be considered in the casting process:

The wall thickness of the tee pipe is the minimum wall thickness, which is also the radial force bearing receptor of the pipe. In order to avoid casting failure cold separation defects, the design wall thickness of the casting shall be less than the minimum wall thickness. In order to reduce cracks shrinkage porosity, the design of the inner wall thickness of the casting shall be thinner than the outer wall. The wall thickness shall be uniform to prevent the formation of hot spots residual stress. The material of the tee pipe parts In order to reduce the shrinkage of gray cast iron, the principle of simultaneous solidification can be adopted to design ensure the quality of castings; the casting structure of the parting surface shall be simplified reduced to avoid curved parting as much as possible, the plane parting shall be used to minimize the parting surface; in order to facilitate the lifting of the mold, the inner outer sides of the casting wall perpendicular to the non machining surface of the parting surface shall be designed with appropriate structural inclination.