The function of vacuum stabilizing system

The vacuum stabilizing system is in fact making the casting sand box under negative pressure, forming a certain pressure through the negative pressure field to apply to the sand grains, which will be beneficial to the compact shape of the sand mold. In addition, the gas produced by the gasification of the high temperature molten metal will also disappear with the pressure field, which can ensure the smooth orderly running of the casting, also ensure the price of the cylinder accessories.

Requirements for vacuum stabilization system

① The power of the vacuum pump depends on the number of sand boxes connected to it.

② The pyrolysis gas of polystyrene is a harmful gas, which should be able to be concentrated discharged at high altitude treated innocuously.

③ It can know the negative pressure value timely accurately, so it is necessary to equip the pressure display device. ④ The equipment shall be equipped with control device stable pressure space to stabilize the negative pressure in the pouring box.

Composition of white vacuum stabilization system

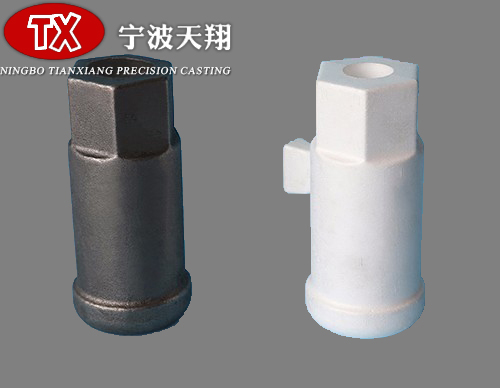

There are many devices that need to be installed in the vacuum stabilization system, which are mainly composed of vacuum pump, stabilization filter box, distribution valve, air-water separation tank vacuum rubber tube. There are two kinds of devices that can be used to install the automatic line of the sand box, one is pneumatic the other is mechanical device, the rubber tube is used to connect the sand box with the vacuum of the stabilization system. In the free position, the vacuum rubber tube is inserted manually. Vacuum pump is the most basic equipment in EPC production. Quotation of cylinder accessories in the production line.

In order to be dust-free in the air meet the requirements of environmental protection for dust emission standards, the mechanical casting factory must pay full attention to the dust removal of the sand treatment system, that is, each dust point should be equipped with a dust suction port.