The theory of casting forming metal liquid forming is often called casting, casting forming technology has a long history. As early as 5000 years ago, our ancestors were able to cast red copper bronze products. Casting is a widely used liquid metal forming process. It is a method of pouring liquid metal into the mold cavity obtaining a certain shape of blank part after it is cooled solidified.

Cylinder accessories factories account for a large proportion of liquid forming parts in machinery equipment, which account for 70% ~ 90% of the total weight in machine tools, internal combustion engines, mining machinery heavy machinery, 50% ~ 70% in automobiles tractors, 40% ~ 70% in agricultural machinery. Liquid forming process can be widely used because it has the following advantages:

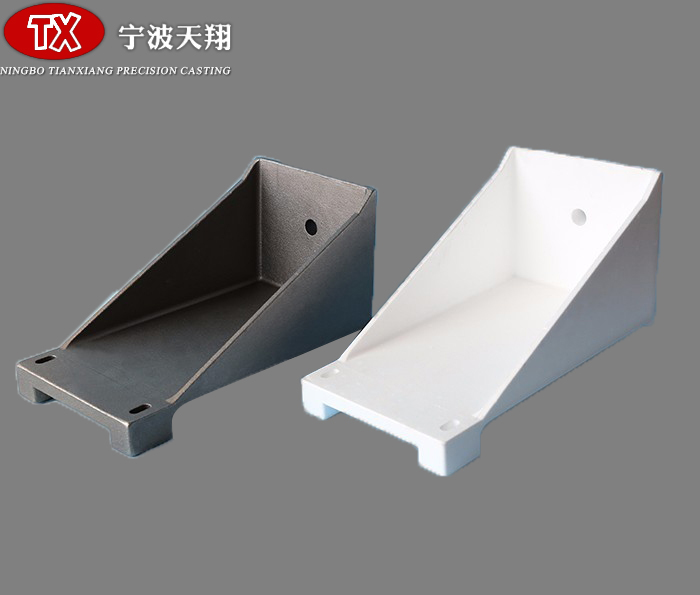

(1) Cylinder accessories can be customized to produce blanks with complex inner cavity shape. Such as various boxes, machine bed, cylinder block, cylinder head, etc.

(2) The machining process of cylinder accessories is flexible adaptable. The size of liquid forming parts is almost unlimited, its weight can be several grams to hundreds of tons, its wall thickness can be 0.5mm to about 1m. In industry, any metal material that can melt into liquid state can be used for liquid forming. For cast iron with poor plasticity, liquid forming is the only way to produce its blank parts.

(3) The cost of liquid forming parts is low. Liquid forming can directly use waste machine parts chips, the equipment cost is low. At the same time, the machining allowance of the liquid forming parts is small the metal is saved.

However, there are many processes in liquid metal forming, it is difficult to control, so the quality of castings is stable. Compared with the forgings of the same material, due to the loose structure coarse grain of liquid forming, the internal defects such as shrinkage cavity, shrinkage porosity porosity are easy to occur. Its mechanical properties are low. In addition, labor intensity is high conditions are poor. It has excellent mechanical physical properties. It can have a variety of comprehensive properties with different strength, hardness toughness. It can also have one more special properties, such as wear resistance, high temperature low temperature resistance, corrosion resistance, etc.

The weight size range of castings are very wide. The light ones are only a few grams, the heavy ones can reach 400 tons, the wall thickness is only 0.5mm, the thick ones can exceed 1 meter, the length can be a few millimeters to a dozen meters, which can meet the use requirements of different industrial departments.