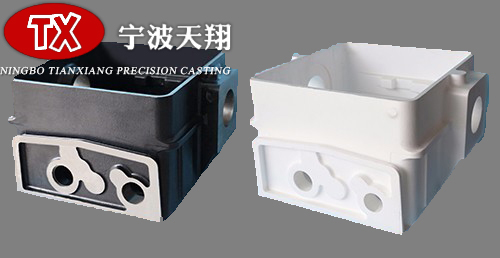

High quality silica sol casting is composed of cylinder, end cover, piston, piston rod seal.

End cap:

The end cover of high quality silica sol casting is provided with an air inlet an air outlet, some of them are also provided with a buffer mechanism in the end cover. The rod side end cover is provided with a sealing ring a dust ring to prevent air leakage the piston rod external dust mixing into the cylinder. The end cover at the rod side is provided with a guide sleeve to improve the guiding accuracy of the cylinder, bear a small amount of transverse load on the piston rod, reduce the downward bending when the piston rod extends, extend the service life of the cylinder. The guide sleeve is usually made of sintered oil-bearing alloy forward inclined copper casting. In the past, the end cover was usually made of malleable cast iron. In order to reduce weight prevent rust, aluminum alloy was often used for die casting, brass was used for micro cylinder.

Piston:

The piston is a pressurized part of the cylinder. In order to prevent gas channeling between the left right cavities of the piston, a piston sealing ring is provided. The wear-resistant ring on the piston can improve the guiding performance of the cylinder, reduce the wear of the piston sealing ring reduce the friction resistance. The wear-resistant ring is made of polyurethane, polytetrafluoroethylene, cloth sandwiched synthetic resin other materials. The width of the piston is determined by the size of the sealing ring the length of the necessary sliding part. The sliding part is too short, which is easy to cause early wear seizure. The material of piston is usually aluminum alloy cast iron. The piston of small cylinder is made of brass.