EPC process flow

Production process of mass production in nodular casting plant. The process includes five parts: melting, mold making, model combination, coating drying, molding pouring sand cleaning.

Classification characteristics of EPC Process

There are two kinds of Automobile Casting price classification. One is based on the properties of its casting materials, which can be divided into dry sand EPC without binder self hardening sand EPC. The second one can be divided into negative pressure EPC common EPC according to the different pouring conditions.

Compared with the traditional sand casting, the EPC process has excellent process characteristics. Under the mass production conditions, the process characteristics are as follows:

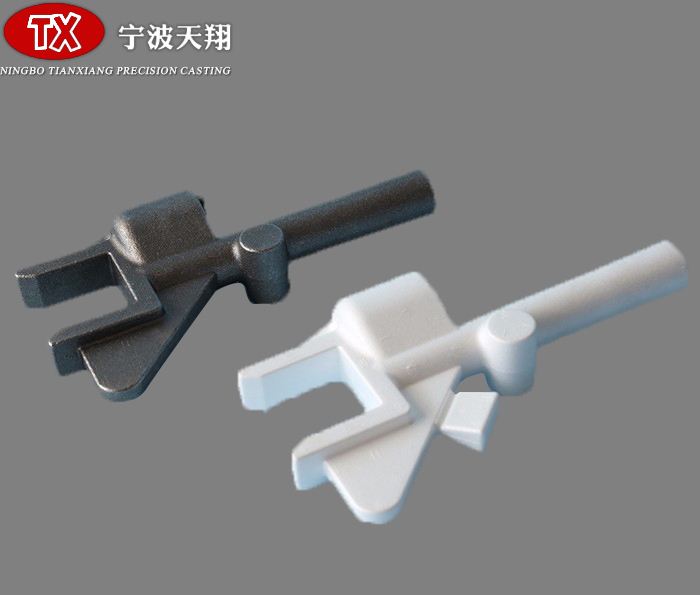

(1) the traditional sand casting is a cavity mold (i.e. "empty type"), lost foam casting is retained in the mold by a foam plastic model that is exactly the same as the casting shape the size of the metal is only bad.

2. During pouring, the high temperature metal liquid decomposes the foam plastic model, so the metal occupies the pattern position, which is different the traditional "empty mold" casting is a metal liquid filled in the cavity. At the same time casting a casting requires a foam pattern.

3. The foam pattern can be divided into blocks according to the structure then bonded to form parts.

④ The dry quartz sand used in the sand mold has the characteristics of no binder, no moisture no additives; in addition, Baozhu sand forsterite sand can also meet the requirements.