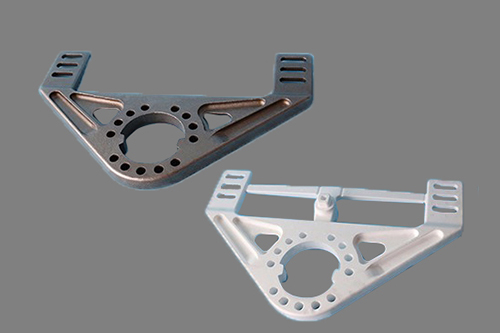

Ceramic mold casting:

The casting method of producing castings by using ceramic slurry to make molds. Ceramic slurry is composed of ethyl silicate hydrolysate fine refractory sand with pure texture high thermal stability, such as fused quartz, diamond, corundum, etc. In order to make ceramic slurry gelled in a short time, calcium hydroxide magnesium oxide is often added as catalyst. Because the refractory used is similar to ceramic in composition appearance, it is called ceramic type. Ceramic mold casting is a new technology developed on the basis of common sand mold casting. There are two types of ceramic mold: ① ceramic mold is made of ceramic slurry. The manufacturing process is to fix the pattern on the molding board, coat the sand box, then pour the prepared ceramic slurry into the sand box. After the gelling hardening, the mold will be started, then the mold will be formed after high-temperature roasting. ② The ceramic slurry is poured into the gap between the bushing the pattern to make the mold. Bushing can be sand metal. Casting ceramic shell with bushing can save a lot of ceramic slurry is widely used in production. The surface roughness of ceramic mold castings can reach RA10 ~ 1.25 μ m, the dimensional accuracy can reach 3 ~ 5 grades, which can achieve the goal of less machining without cutting. The production cycle of ceramic mold casting is short the metal utilization rate is high. The castings can reach more than ten tons, which are mainly used for casting large-scale thick wall precision castings casting single small batch dies, forging dies, plastic dies, metal dies, die-casting dies, glass dies, etc. The service life of ceramic mold is comparable to that of the mold made by machining, while the manufacturing cost of railway casting is lower than that of the mold made by machining.