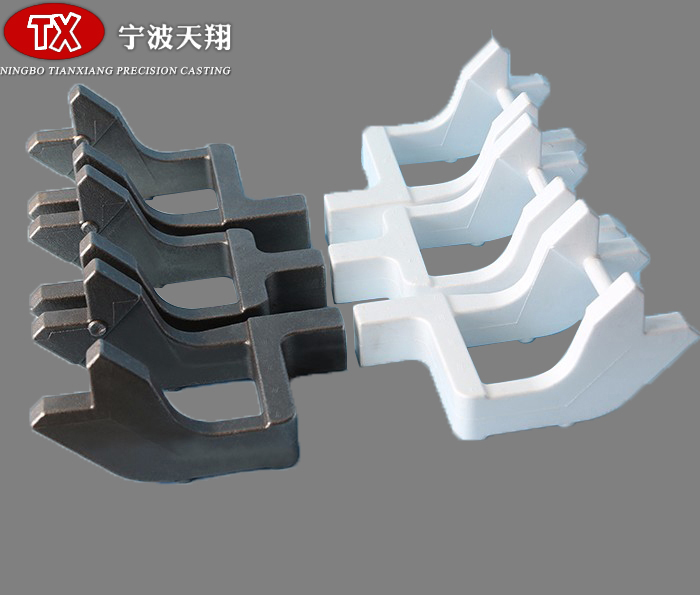

Special casting

Investment casting, low pressure casting, pressure casting, centrifugal casting, metal mold casting, dewaxing, continuous casting, vacuum casting. Centrifugal casting, etc

Differences advantages of precision casting sand casting

Precision casting: the railway casting factory first makes the appearance of the wax part, that is, the casting, then hangs the slurry on the wax mold sticks the sand to form a solid shell on the surface of the wax part. Next, it heats up, drains the wax, pours the molten steel aluminum water into the empty shell, cools shakes the shell to get the desired casting. The surface quality size of the precision casting are high; sand casting is also called sand turning. First, make the appearance of the casting with wood. Generally, the material selected is wood, metal mold is also used. Bury the wood mold in the sand, then take out the wood mold, so that the sand becomes a mold cavity. Pour the molten steel out of the cavity cool it down to the desired casting pattern. The surface quality of sand casting is poor, the size is inferior to that of precision casting, but the price of shaft sleeve casting is lower than that of precision casting. If the batch is large the die-casting mold is used, the output is high the cost of a single piece is low; compared with the precision casting mold sand casting mold, the cost of the die-casting mold is higher.