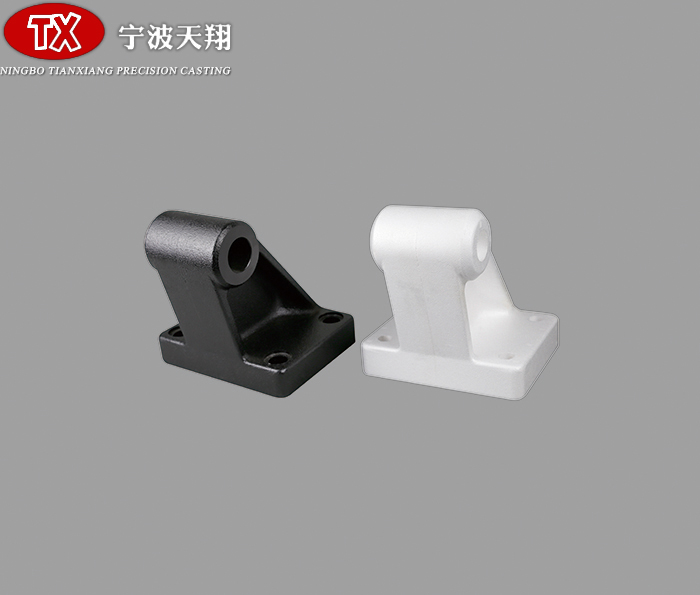

Material is QT450

common problem

The thickness of customized furnace charge for aluminum alloy casting of TV support shall be in accordance with the regulations ensure symmetry. Too thick furnace charge for high-quality railway casting will reduce furnace volume efficiency; too thin furnace charge is prone to safety accidents. The raw materials for processing furnace building of aluminum alloy casting for TV bracket shall be clean tidy, shall infiltrate gravelly soil, iron pin, wood slag, grass scraps other dirt. The charge must be tamped the compactness is even.

The newly built furnace charge must be calcined according to the processing technology, can be applied after calcination.

The furnace charge after the repair of high-quality EPC casting shall be baked calcined as necessary: after the repair of the furnace charge, the return scrap which is leveled on the surface during the discharging shall cling to the repair place, the furnace charge shall be heat treated with a slightly lower output power to the redness of about 800 ℃, the heat insulation heat preservation of about 1h to bake the repaired furnace charge, then the melting shall be carried out as per all normal work. For the material repair area with a larger total area, it should be baked calcined, the metal material solution should be maintained 90mm below the repair area. After a proper time, the metal material solution should be raised to resume work.

Processing technology regulations:

Steel non-ferrous metals must conform to the specified composition.

The waste materials returned to the furnace shall be clean, dry, rusty free of dirt.

The recycling waste of different materials should be separated piled up.