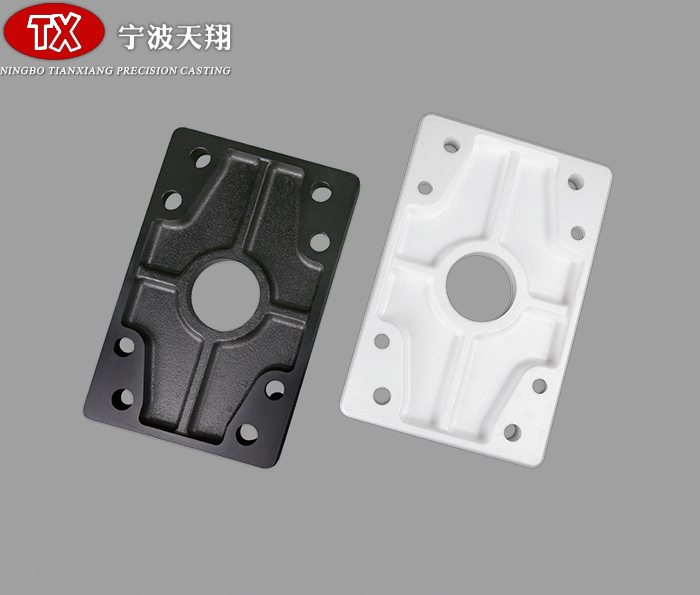

Material is QT450

Regulations on processing technology of shell culture firing

Kerosene furnace firing temperature: General Parts 1150 ℃ miscellaneous parts 1200 ℃ unique parts 1300 ℃ high temperature furnace firing temperature: General Parts 1100 ℃ miscellaneous parts 1150 ℃ unique parts 1200 ℃ firing time: > 30min, thermal insulation time: > 30min

Operation process

The supplier of silica sol casting shall check whether the calciner temperature control table are normal whether the furnace bed is neat.

The shell to be fired shall be complete free defects, the defective shell shall be restored.

Clean the edge of rubber inlet cup of high-quality shaft sleeve casting, resolutely prevent sand falling into the shell.

Be careful to install the shell into the calciner the rubber cup, the shell poured after that shall be installed first, the shell shall be no less than 20cm away the furnace mouth.

Close the furnace mouth, start the fire raise the temperature. The temperature control in the furnace is within the specified temperature range, the heat insulation time of the shell is more than 30min, the cultured shell shall be milky white rose color.

The purpose of shell culture: to remove the volatile organic compounds such as water, residual mold material, acetate soap residue, so as to reduce the temper improve the permeability of shell; to improve the phase composition of shell to improve its high temperature characteristics. It is beneficial to the pouring of hot shell to improve the filling capacity of metal material liquid.

The calciner forging heating furnace shall cooperate with each other to ensure that the shell is burned well during pouring maintain high temperature. When the molten iron reaches the standard can be poured, open the furnace mouth of the calciner fork out the shell for pouring. It is specified that the shell can be forked out of the calciner for more than 10s.

Note: in continuous production, shell can be hot charged.