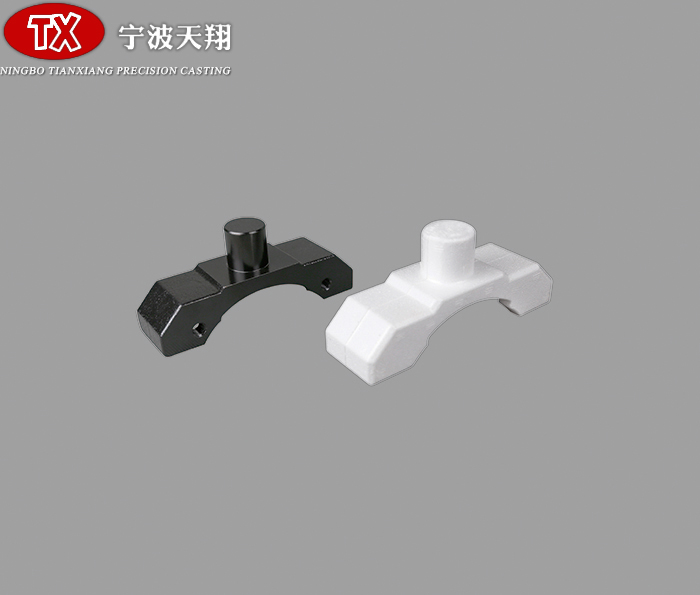

Material is QT450

Smelting operation flow

The manufacturer of silica sol casting shall open all cooling circulating sluice valves. The pressure shall be less than 0.15Mpa.

Put the waste into the furnace. Discharge standard: the carbon concentrate with high melting point, difficult to melt difficult to be oxidized by air shall be loaded into the bottom, the carbon concentrate with low digestibility shall be installed at the bottom of the furnace. A small piece shall be added at the bottom the middle, the feeding is inseparable, so that the electromagnetic field is gathered the melting is fast due to the waste material returned to the furnace. . the upper end of the block is loose, so that its weight can be lowered to prevent "bridging".

The high-quality cylinder accessories are connected to the switch power supply according to the operation specifications of the high-frequency semiconductor material DC frequency conversion equipment. Adjust each power factor (meter) to make smelting develop rapidly.

When the recycling waste is melted, carry out the feeding add the remaining recycling waste until it is full.

When the liquid level appears at the beginning of the melting of the waste in the furnace, a proper amount of slag making agent (covering agent) should be added to reduce the contact between the liquid level of the metal material the gas, reduce the respiration air oxidation.

When all the recycling wastes are filled melted, the old slag shall be removed to make new slag. keep the liquid level of metal material covered.

When the temperature of metal material liquid rises to 1550 ℃, add manganese ferrosilicon to carry out deamination, including the filling of manganese silicon elements.