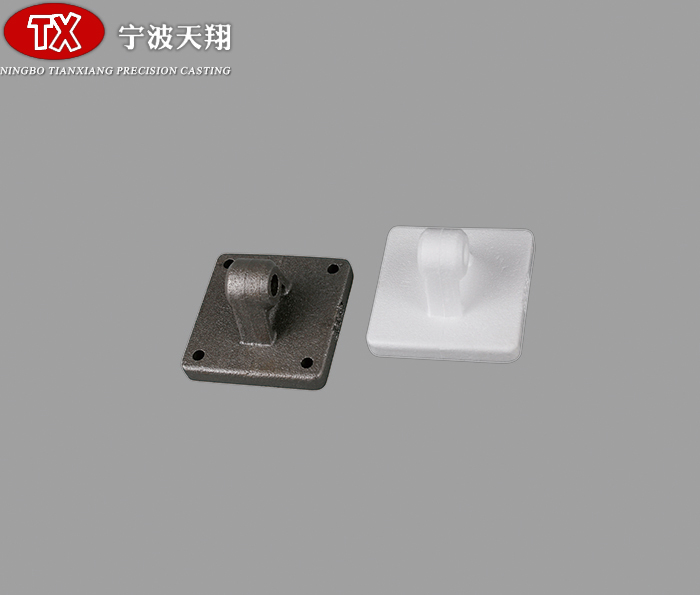

Material is QT450

At present, the advantages disadvantages of the key shell making process in the production manufacturing of China's investment casting are as follows:

A. Sodium silicate shell; B, composite shell; C, silica sol shell; D sodium silicate shell has been manufactured in China for nearly 50 years, its factory grade still accounts for a very large proportion in China's precision casting manufacturers. In recent years, the EIA of EPC Castings has been promoted by the improvement of the back layer shell refractory the application of new sealing curing agent. The compressive strength of sodium silicate shell has been multiplied, the technological performance, specification precision production rate of castings have been greatly improved. The low cost, low production cycle, high quality exuviating characteristics high air permeability are still inferior to other shell processing technologies.

Key problems

(1) The defect of sodium silicate adhesive is that the Na2O component is high, the high temperature compressive strength stress relaxation resistance of shell are far inferior to that of water-soluble silicone resin shell. In addition, shiyingsha (powder) with low price quality poor particle size distribution mix ratio is selected as the overall surface fireproof material, so it is necessary to get high-quality precision casting parts.

(2) Standard deviation of shell production manufacturing, lack of strict processing process operation of main parameters. Due to the strong corrosion of the sealing curing agent, the dust remover equipment is simple, very few production workshops have the environment of temperature control, humidity control ash removal. The construction coating configuration, hard bottoming, blow drying, dewaxing other technological processes endangering the quality of shell casting parts are rarely strictly controlled according to the operation specifications required by the manufacturing industry. The temperature, environmental humidity wind force at the blow dry position of the shell do need to be manipulated, so a large number of safety accidents are reported in high, ultra-low temperature Meiyu weather. All in all, the vast majority of processing plants stay in the manual workshop, relying on technology rather than scientific research quality control to carry out production manufacturing. It is one of the key reasons for the unstable quality, unqualified rate high failure rate of sodium silicate shell castings in recent decades.