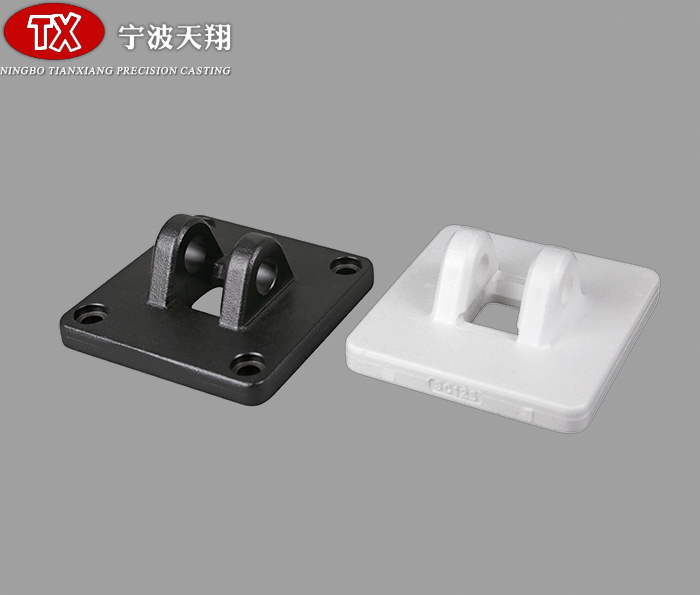

Material is QT450

Practical operation rules of wax sprue tube processing technology for precision casting suppliers

Regulations on processing technology

Indoor temperature 22 ℃± 2 ℃

Injection wax temperature 70-75 ℃

The curing time depends on the type of sprue

Operation process

Overall sprue suppression

The precision casting manufacturer shall check whether the standard air pressure, holding barrel temperature, actual operation buttons, etc. of the material pipe wax pressing machine are all normal, adjust the main parameters such as the injection working pressure of the equipment according to the technical requirements.

Place the runner (material pipe) abrasives on the surface of the equipment table, check whether the wax nozzle of the equipment is consistent with the height of the wax injection mouth of the abrasives, whether the opening closing of the abrasives are complete,

Open the abrasives, spray a little clinical diagnostic agent, place screw cap, close the abrasives, point to the wax nozzle.

Press the key in the working process with both hands to restrain the sprue (material pipe) wax mold.

At the end of inhibition, pull out the mandrel, open the grinding tool, take off the sprue (feed pipe) wax mold carefully, put it into the cooling circulating water. Pay attention to the defective reimbursement.

Remove the residual wax the abrasives.

Spray clinical diagnosis agent, put screw cap, close type, carry out the next inhibition, so as to manufacture reciprocating circulation system.

Remove the wax sprue after it is cooled for 3-5min, then blow the water drop with air compression, put it to a specific place.

After each shift is off duty the application of abrasives is completed, the machine equipment abrasives shall be cleaned up.