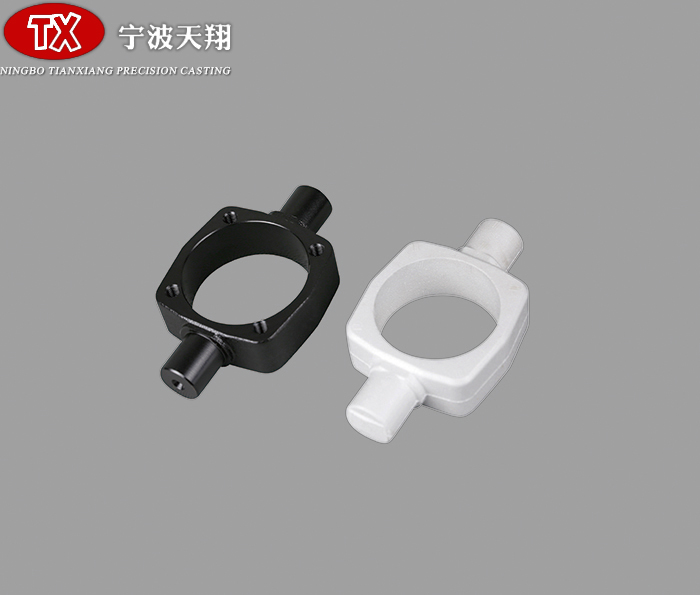

Material is QT450

Common problems of precision casting manufacturers

There is no need to spray too much clinical diagnostic agent into the grinding tool die.

The surface layer of wax sprue (material pipe) shall be leveled free of dents, cracks draping joints. If there are cracks, dents, bubbles other defects in the wax sprue (material pipe), repair shall be carried out, the unrepairable fees shall be paid.

Do a good job in the safety production of the bet material pipe. When the cylinder head of the wax standard air cylinder is tightened, it is forbidden to open the air compression to the main cylinder. When the air compression is turned off the residual air of the main cylinder is completely discharged, it is forbidden to open the cylinder head.

The safety fire prevention work should be done well in the wax mould room. Practical operation criterion of wax mold renovation processing technology 1 processing technology regulation indoor temperature 22 ℃± 2 ℃ 2 operation process

The manufacturer of precision casting shall check that the external water angle of wax mold is clear, the surface is smooth smooth, there is no defect, the specification is in line with the regulations, there is no change.

Mold repair

Carefully gently scrape away the burr parting line along the surface of the wax mold with the blade tooth surface, do damage the wax mold. You can also wipe off the small flash immediately with a cloth.

The concave part of wax mould shall be repaired with repair wax, the surface shall be leveled after repair.

The blister on the wax mold must be punctured repaired with repair wax.

The wax mold wrinkles of the castings with the specified height must be repaired, leveled polished.

Use air compression nozzle to blow the wax scraps clean put them into the storage drainage plate as required.

Check after mold repair: check whether the wax mold is detailed, deformed, the surface is smooth whether the handwriting is up to the standard.

At the end of the work, clear the scene.