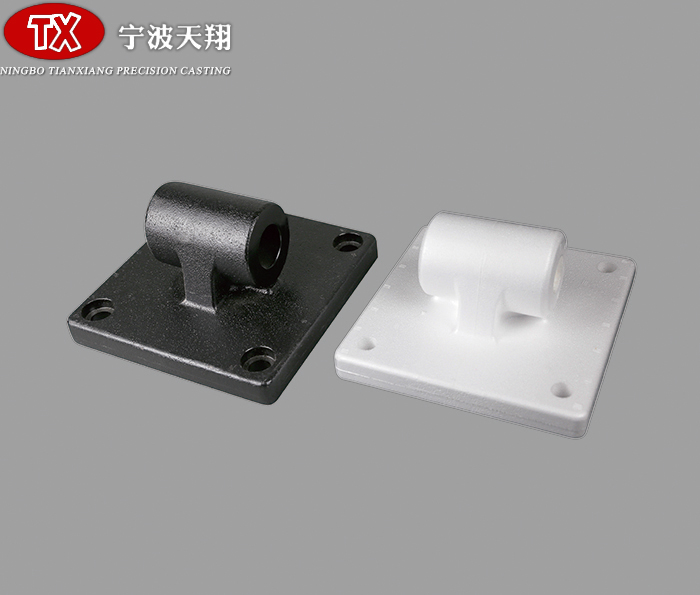

Material is QT450

common problem

The electric welding between the wax mold the sprue in the precision casting plant shall be firm without gap.

The wax mould welded by electric welding on the same wax mould group must be the same raw material quoted by zinc alloy die casting.

If there is wax liquid on the wax mold, the wax drop shall be cleaned.

Safety tips: disconnect the switch power supply at the end of work. do a good job in safety fire safety work.

Practical operation rules of mould group cleaning process

Regulations on processing technology

Detergent zf-301, etc

Indoor temperature 22 ℃± 2 ℃

Operation process

Prepare cleaning fluid according to the proportion mix.

Remove the wax touch group on the assembly welding after standing for 45min the transport car. First, thoroughly infiltrate the touch group into the cleaning solution, continue to reciprocate for three times for 5S. When the touch group is mentioned, drop the liquid.

Remove the wax touch group compress with air to dry cool the touch group.

Lift the cleaned module onto the transport car.

Actual effect of sample inspection group cleaning:

2 groups the same batch of cleaning touch groups to infiltrate silica sol (add 0.5% wetting agent with capacity), check whether it is completely wet after extraction.

It can be thoroughly wetted to show that the actual cleaning effect is excellent. The touch group can be immersed in water to remove silica sol, the water can be blown away by air compression, then hung off the transport car for standby.

If the touch group can be completely wet, the whole batch of touch group must be cleaned again.