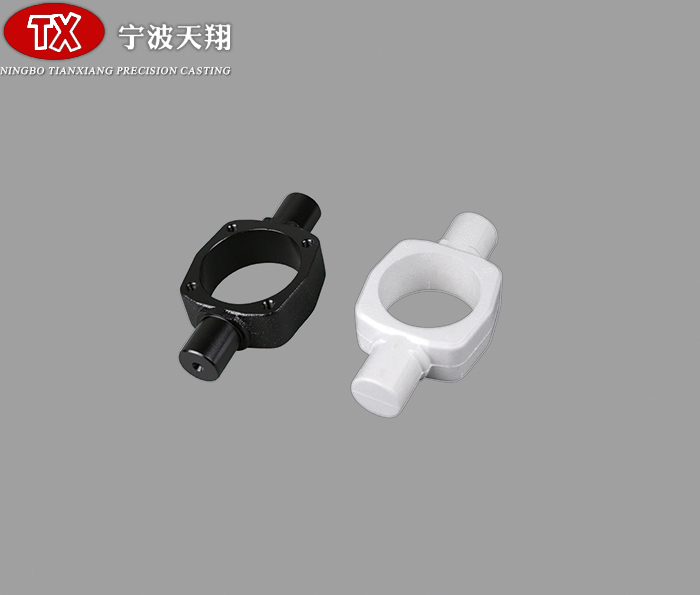

Material is QT450

Common problems of zinc alloy die casting suppliers

If the liquid level drops, fill in the new liquid immediately. If there is milky white block like environmental pollution, it should be placed for 24 hours, 2 / 3 clean water solution should be sucked out, other dirty liquid should be thrown away, new liquid should be filled, then it can be reused. (it can be used for 40 days 6000-8000 groups every time when cleaning liquid is prepared)

During the whole process of cleaning liquid application, the falling wax mould shall be removed immediately. After application, remove all out of town characters store them in a sealed lid.

Zinc alloy die casting manufacturers should have ventilation machines equipment in the cleaning room of the mould group, the gas should be circulated. prohibit fireworks, do a good job in safety fire safety work.

The silt content in the sand shall exceed 0.30%.

The grain number of mullite is: 16-30 mesh; 20-40 mesh; 30-60 mesh; 50-80 mesh.

The particle size distribution of mullite powder is 315 mesh 275 mesh. 220 mesh.

The raw materials entering the factory every time shall be attached with the quality certificate of the products. The name, specification model, net weight, manufacturer time of consumables shall be printed on the surface of the packaging bag. During transportation storage, avoid moisture rain, store in different specifications models.

Performance parameters of machinery equipment for building coating shell making applications.

Agitator: 380v2.2mw50hz model specification zj-0600 (0800) specification 1400 × 1000 × 1100 (mm)

Sand shower: (ls-x) 380v1.5kw50hz

Floating sand machine: (FS-X) 380v4kw60hz