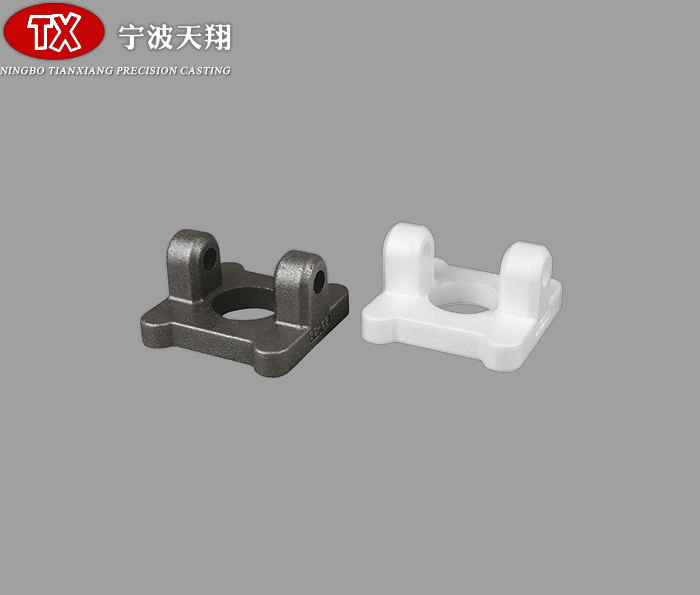

Material is QT450

common problem

It is allowed to add sodium hydroxide solution to the tank body under the condition of heating. (because it's dangerous)

When the casting parts are put into taken out of the alkali boiling tank, they should be handled with care to prevent the caustic solution splashing to death.

The fastening equipment of the lock of the import export trade cover of the hardness barrel of the EPC casting the drive mechanism of the alkali boiling should always be checked reliable.

Inspection items

If the residual shell aluminosilicate on the casting is cleaned, it shall be alkali boiled cleaned again.

The bath temperature is often inquired the NaOH composition of the alkaline cooking solution is analyzed on time, the relative density is measured.

Laser cutting rubber inlet

Regulations on processing technology

The capacity of the rubber inlet in the casting shall be 3-mm for the fine cut casting ≤ 3mm for the polished casting.

Operation process

Wear labor protection equipment.

Check whether the protective cover of the equipment is intact.

Install tighten the sand wheel blade woodworking saw blade, then start the idling for 1-2 minutes to keep the machine equipment in all normal conditions. Pay attention to the stable rotation of the angle grinding blade.

Fix all the casting parts on the proper part of the grinding wheel cutting machine.

Start the automatic cutting machine to point to the internal sprue, cut the casting according to the rubber inlet capacity specified by the processing technology.

Put the disconnected casting parts billed casting parts into different boxes according to the type of aluminum alloy, hand them over to the warehouse according to the regulations.

After laser cutting, the rubber inlet bar shall be distributed to the position required by the mark according to the aluminum alloy model. Don't confuse.

After the end of the work, clean the working environment remove the machinery equipment.