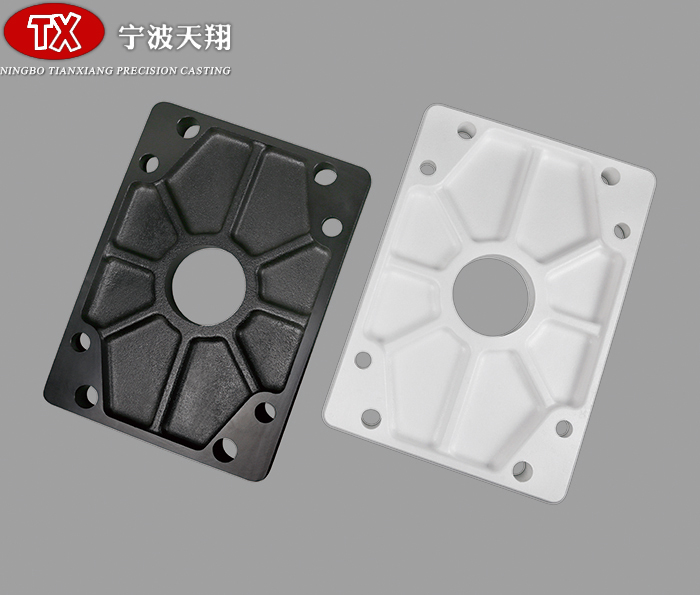

Material is QT450

Common problems: (production safety shall be ensured without accidents)

Under all conditions, high quality zinc alloy die-casting parts shall leave imprints scars on the products, the casting parts shall have deformation.

The vibration shell time shall be too long, shall be less than 2 minutes to prevent cracks of casting parts.

High quality TV bracket aluminum alloy casting alkali boiling cleaning is used in the hot solution of sodium hydroxide solution (NaOH) to clean the casting shell.

Regulations on processing technology

Sodium hydroxide solution (NaOH) concentration value: 20% - 30%, relative density: 1.2-1.3g/cm3. ( 25%, 1.3g/cm3.)

Alkali boiling temperature: 100-110 ℃

Alkali boiling time: it depends on the size of casting parts the amount of residual mold sand; generally, the alkali boiling barrel is one time faster than the static method.

High quality TV bracket aluminum alloy casting cleaning Zhonghe. (it should be cleaned up above 80 ℃ with boiled water mixed with sulfuric acid.)

Operation process

The high-quality shaft sleeve casting is made by hand the alkali boiling barrel is used to remove a lot of residual sand skin at the surface layer, deep hole, buried hole blind area of the casting.

Static release method: after the concentration value of the alkali boiling solution meets the requirements, put the casting into the alkali boiling basket into the alkali boiling tank; turn on the heating device, raise the temperature of the alkali boiling solution to the required temperature, keep it for a period of time; turn off the power supply, remove the casting place it in the cleaning tank for cleaning; then remove the cleaned casting remove the cool dry shot blasting for rust removal.

Rolling alkali boiling method: install the casting parts into the rolling Jane, with a larger carrying capacity of 1 / 2 of the rolling barrel capacity, fasten the import export trade cover; enter the steam into the alkali boiling tank, warm the alkali boiling liquid to meet the requirements, start the gear transmission to work for a period of time; terminate the steam heating, loosen the tightening equipment, remove the casting parts for cleaning, cool dry shot blasting to remove rust.