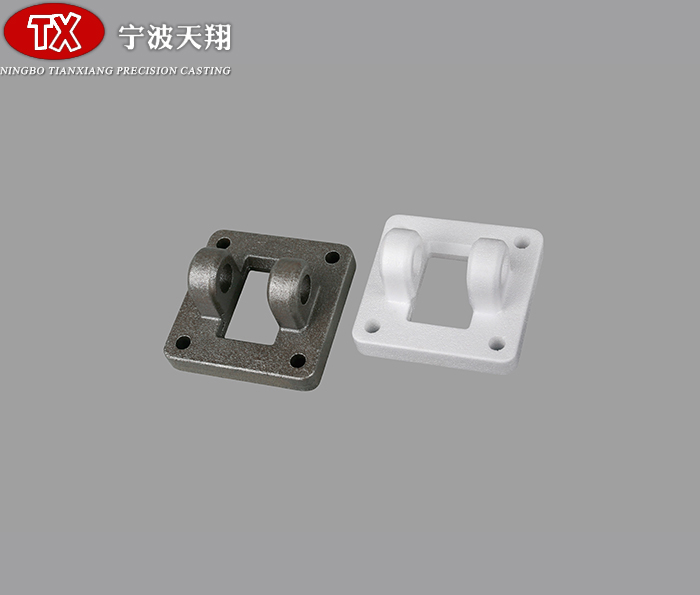

Material is QT450

Blast cleaning

Regulations on processing technology

Sand blasting shall be used to remove the castings with low roughness specified by EPC casting negative pressure. For sand sprayed castings, it is necessary to do a good job in rust prevention.

Operation process

Check if everything is OK.

Put the casting into the work basket, start the sand blasting equipment, sand blast the surface of the casting.

The lost foam casting shall be bonded with sand wear gloves to remove the sand sprayed casting recheck it into the warehouse.

At the end of work, cut off the power, remove the machine, equipment places.

common problem

Common machine sand is allowed to have too much dust, otherwise, it is necessary to screen powder to remove dust before reuse.

Check whether the nozzle diameter is suitable, the spray gun sand suction pipe shall be free blocking the sewage pump.

For castings with long fine holes, when the inner shell of the hole cannot be eliminated, the alloy drill can be used to drill out the small medium shells of the hole before sand blasting, so as to facilitate sand blasting.

For castings with long fine grooves font style, HF acid can be used to soak for more than ten minutes to dozens of minutes before sandblasting, so as to facilitate sandblasting.