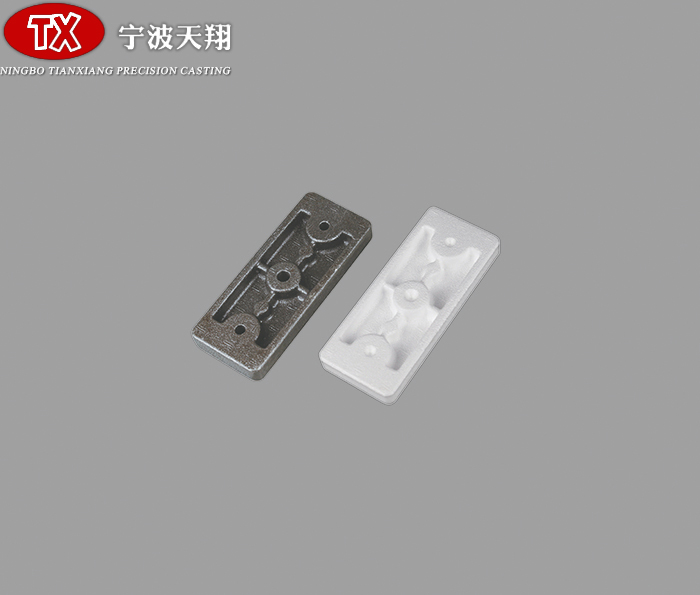

Material is QT450

Regulations on processing technology

Passivator preparation

HNO3 (98%:) HF (31%:) H20 (purified water) = 6:5:51.2 passivator temperature 55-65 ℃

Cleaning frequency 3-5 times 2 operation flow

According to the proportion of passivation treatment, mixing, adjust the environmental humidity.

For the acceptance of EPC Castings, the castings requiring stainless steel passivation shall be put into passivator for 2-5 minutes.

Remove the casting the passivator immediately put it into the hot water reservoir for cleaning 3-5 times.

Then wash with cold water 3-5 times.

After that, put the casting into the open water tank for cleaning 3-5 times.

Dry the casting with air compression.

common problem

Before passivation treatment, the castings shall be cleaned by shot blasting, the castings shall be passivated immediately after shot blasting.

Often check whether the passivator is invalid. If it is invalid, it should be configured again according to the proportion.

The invalid passivator should be collected transported in the special vessels, should be poured at will to avoid environmental pollution.

The actual operation personnel shall wear protective equipment before carrying out the actual operation.