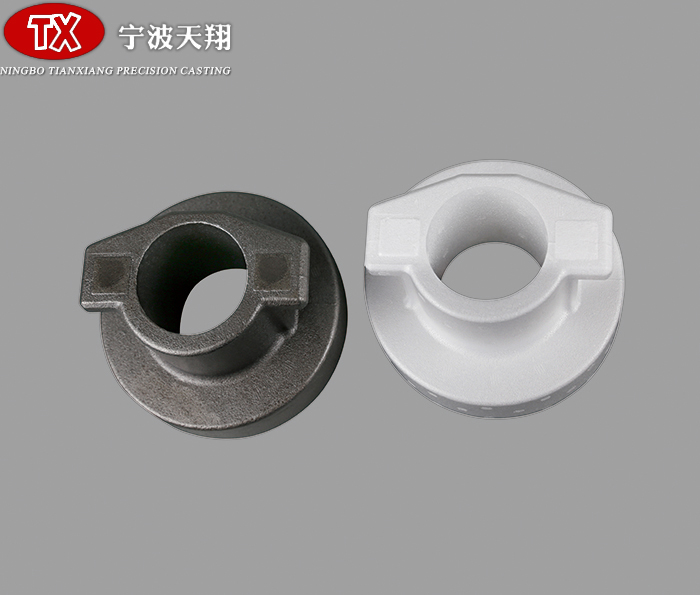

Material is QT600

It is allowed to use medium temperature wax for composite shell. Dewaxing with boiling water is allowed for medium temperature wax. When dewaxing in high-pressure reactor, due to high temperature high pressure, medium temperature Dama resin will cause strong saponification reaction with sodium silicate residual sealing curing agent in the back layer, which can be reused without purchase.

Silica sol shell

In the 1960s, the silica sol for EPC casting of cast steel was used as the adhesion agent of porcelain shell mold in the forging industry. With its incomparable advantages, the supply of EPC casting gradually replaced the sodium silicate magnesium chloride ethoxylate hydrolysate, which were widely used in the past had complex processing technology, environmental pollution increased cost. Practical experience shows that using silica sol solution as porcelain shell type adhesive has the following advantages: simple processing technology, convenient storage of building coating, re application of the slurry after adjustment of components, low consumption of raw materials, stable application performance of dip coating, easy practical operation, elimination of ammonia drying when using magnesium chloride ethyl ester hydrolysis reaction solution, improvement of office environment With controllable environmental humidity high compressive strength of shell type, water-based silica sol is selected with good safety factor. It is reported that after the conversion ethyl silicate to silica sol, the energy consumption is reduced by 20-30%, the shell type compliance rate is increased by 15-20%, the office environment is greatly improved.

Silicasol (low temperature wax) shell

Low temperature wax forming is very easy, machinery equipment are simple, wax mold roughness is large, processing technology is stable than composite shell quality, especially the casting parts are of high precision, because it does have sodium silicate, high temperature characteristics of shell, high permeability of shell after firing, strong stress relaxation resistance, only can be used for thin-walled parts, complex structure of large medium-sized parts, but also can be produced Make large objects weighing about 50-100kg.