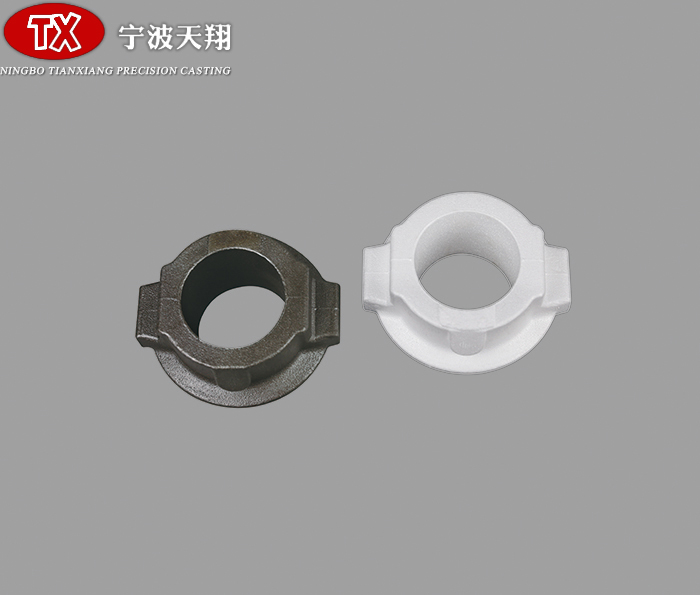

Material is QT600

There are some unavoidable defects in these kinds of shell making processes. The water glass process specification precision is poor, the quality is stable, the unqualified rate, the failure rate is high, many times, the waste only extravagantly wastes the resources but also causes the damage to the company. The complex shell processing technology improves the difficulty coefficient of process management, in order to save the project investment, the reliability of quality is weaker than that of silica sol in terms of machine equipment, raw materials, natural environment, etc.; sometimes, due to the improvement of failure rate unqualified rate, the cost of specific products will be higher than that of silica sol processing technology. Although the processing technology of silica sol shell is of high precision low consumption environmental pressure, the production cycle of shell making is too long. When the silica sol adhesive shell is used to produce casting parts, it can obtain good process performance specification precision because of its high compressive strength. In addition, because of its high residual compressive strength weak collapsibility, it is very difficult to clean sand hard. In addition, with China's accession to the WTO the transformation of the international investment casting market environment, a lot of order information of precision casting parts in Britain Europe has been transferred to China, the demand for stainless steel metal products high-precision mechanical parts in China's sales market has also been greatly expanded, because the supply cycle stipulated by customers is becoming shorter shorter, the forging companies are driven to reduce under the premise of ensuring quality Production cycle. Therefore, as a new generation of China's fast drying silica sol, zf-801 fast drying silica sol has undoubtedly become a more ideal choice for today's precision casting shell processing technology.

Quick drying principle

The customized zf-801 quick drying silica sol for carbon steel casting belongs to the reinforced quick drying silica sol. Compared with the general silica sol, it can quickly create the wet compressive strength of the shell, improve the wet compressive strength of the shell, thus greatly reducing the dry manic time of the shell virtual beam. The water insoluble organic fiber can play a capillary role in the whole process of drying heating, accelerating the evaporation of internal water, the chemical fiber will be burned out in the whole process of high temperature culture burning, so that the shell can produce external economic porous materials improve the permeability of the shell. The addition side of the polymer has the physical binding effect on the silica sol sealing adhesive, can reduce the concentration value of the critical value of the silica sol gel quickly achieve the concentration value of the gel, thus greatly reducing the drying time of the virtual beam. In addition, the polymer can improve the efficiency of shell. Because the polymer solution itself is a kind of adhesive has excellent demulsification, it will continue to improve the spread of silicone rubber in powder sand. The improvement of the affinity between the binder the wax film is beneficial to sizing. The good demulsification property is strong after extraction drying. Therefore, the compressive strength of the shell at room temperature is increased, the shell is easy to crack after membrane removal, so as to ensure the shell quality, improve the shell making speed, also reduce the secondary waste in the middle later process, which only saves the power energy, but also greatly reduces the power waste It has also generated profits for the company.