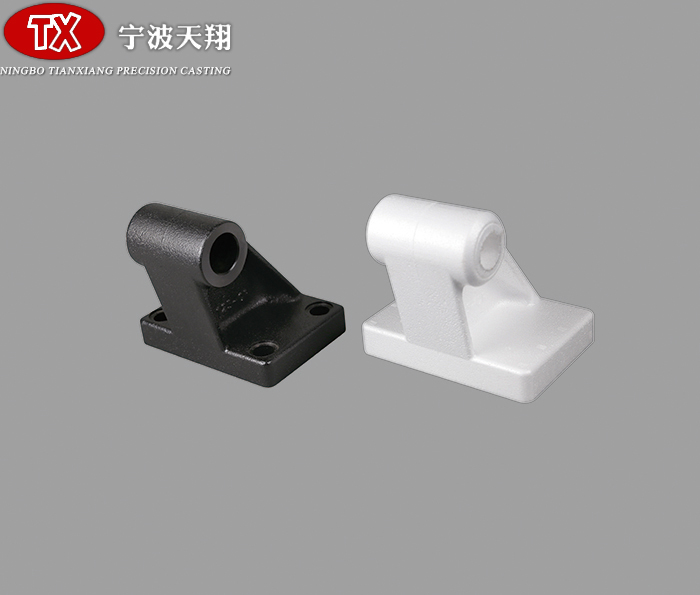

Material is QT450

Shell making operation flow

The zinc alloy die casting manufacturer shall check the mould group to be up to the standard, clean it to be completely dry. In addition, check whether the marks on the touch group conform to the material requirements on the quality tracking card ( process card); if there is any doubt, make it clear immediately to prevent redundant adverse effects.

The viscosity mixing time of the construction coating slurry to be used shall meet the requirements of the processing technology.

During the inspection work of zinc alloy die casting manufacturer, the temperature environmental humidity between dryness impatience shall be specified.

Soaking the whole surface layer pre wet slurry: take down the mold group the mold base car, slowly penetrate into the pre wet slurry the up down angle of 30 °, rotate slightly, then take down at a slightly faster rate to remove unnecessary slurry drops, blow off the bubbles at various positions with air compression to make the mold group evenly apply a layer of thin slurry.

Coating the whole surface slurry: slowly infiltrate the pre wetted slurry into the architectural coating slurry (the whole surface) at an upper lower angle of view of 30 ℃, rotate it slightly, so that the pipe trench, corner, character code, pattern design, buried hole buried hole on the wax mold can be coated with the architectural coating, then take it down at a slightly faster rate, blow off the bubbles at various positions with air compression; in addition, rotate the mold constantly, Remove unnecessary slurry. To produce a detailed uniform coating. (it should be noted that when the post construction coating cannot be applied to the small complicated positions on the wax mold, please use a small brush to dip in the slurry brush reapply the slurry; ensure the quality.)

Sanding of the whole surface layer: extend the touch group coated with symmetrical architectural coating into the sand shower for multi-directional rotation, so that the surface layer is evenly covered with a layer of staggered quartz sand.