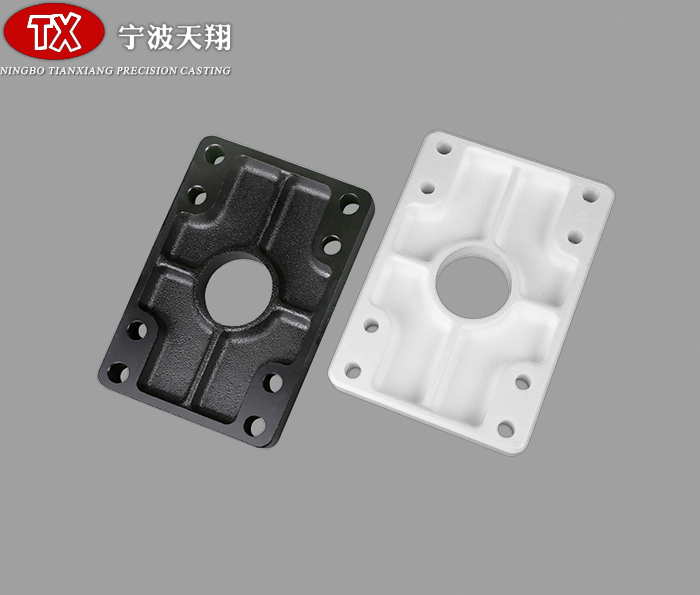

Material is QT450

common problem

For high quality agricultural castings, all raw materials auxiliary materials added to the furnace must be free of paint, serious rust oil stain, so as to reduce the generation of steam body in the furnace.

In order to ensure the safety of high-quality agricultural castings, the materials added in the liquid shall be heated to completely remove the moisture, so as to prevent explosion when adding cold materials water-containing materials.

Cold material removal feeding. It is forbidden to knock against the cold furnace force to prevent cracks in the furnace.

During the whole smelting process of low carbon steel castings, it is necessary to check the temperature of cooling circulating water of electromagnetic induction coil check whether there is any abnormality around the electromagnetic induction coil, so as to detect the leakage of furnace in advance prevent the occurrence of safety accidents.

The furnace workers the pouring workers should coordinate closely so that the smelting announcement the shell mold firing time are in the situation.

The pouring work of furnace workers must clearly grasp the drawing number structure of each commodity, then clearly announce, pouring temperature, water flow working pressure according to the process card to ensure the casting quality.

Furnace workers pouring workers must wear workers' protective equipment follow the actual safety operation guidelines. Ensure production safety without accidents.