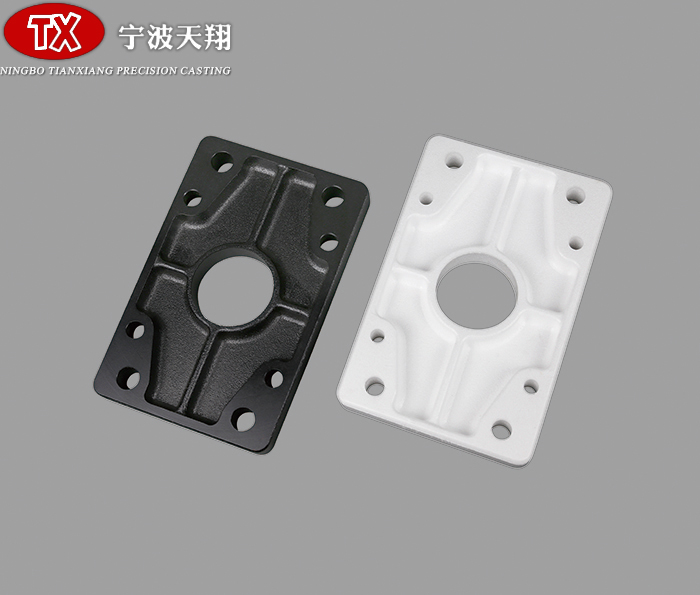

Material is QT450

Shell shaking machine

Check whether the bronchus high-pressure hose of the equipment are properly connected reliable; open the main air compression gate valve check whether the operation of the equipment is normal; check whether the working pressure of the gas should be no less than 0.45-0.65mpa.

Place the casting group vertically under the high chromium alloy hammer head of the shell vibrating machine, open the air inlet valve to make the high chromium alloy hammer head tighten the casting group; align the tooling fixture mold thimble with the rubber inlet bar management center, form an angle of 170 ° - 180 ° between the casting group the mold thimble.

Turn on the vibration shake off the shell on the casting. The vibration time depends on the characteristics of the casting. It is better to eliminate the cleanness of the shell on the casting.

Turn off the vibrator, loosen the clamping equipment, take down the casting group; classify store the casting group of the same material.

After finishing the work of high-quality bucket tooth casting, clean the working environment, remove the machinery equipment, maintain the oil.

Manual shell cleaning

Carefully check the special tools make sure they can be trusted before you start to work.

Place the casting group vertically on the cushion block the required place, hammer the rubber inlet bar with hammer head, then hammer continuously until the mold shell is clean; it is forbidden to hammer the casting.

Clean the working environment after work.